In the ever-evolving field of drilling engineering, tool reliability and efficiency are crucial to both the safety and success of complex operations. Among the many specialized components that make up a downhole drilling system, the circulating sub plays a pivotal role. It ensures the smooth circulation of drilling fluids, prevents downtime, and contributes to wellbore stability. Saigao Group, a globally recognized manufacturer of high-performance oilfield equipment, provides dependable circulating sub designed for optimal performance in diverse geological conditions.

Understanding the Function of a Circulating Sub

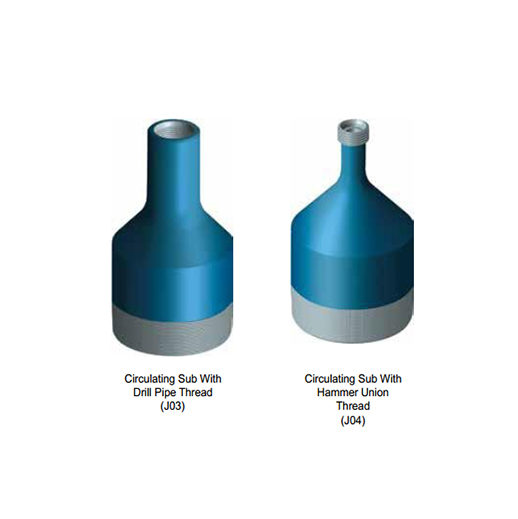

The circulating sub is a critical part of the drill string, used to establish or restore fluid circulation within the wellbore. Its primary function is to redirect the flow of drilling mud or other fluids when the normal flow path is interrupted or requires modification. It is particularly useful during specific stages such as well control, hole cleaning, or maintenance procedures. When activated, it allows operators to pump fluid directly into the annulus or the drill string, depending on the operational needs.

Saigao’s circulating sub are manufactured with high-grade materials and precision engineering, ensuring they maintain performance under high-pressure and high-temperature environments. Their simple yet robust design allows them to integrate seamlessly into various drilling systems.

Applications in Complex Drilling Environments

Circulating sub are widely used in oil and gas exploration, particularly in deep well drilling where maintaining consistent mud circulation is vital. Their ability to provide alternate flow paths proves essential in scenarios involving stuck pipe, bit plugging, or lost circulation zones. In such instances, the use of a circulating sub can reduce the need to pull out the entire string, saving time, labor, and costs.

Moreover, they are frequently employed during operations requiring fluid displacement, cementing support, or injection tasks. The design of Saigao’s circulating sub accommodates a wide range of operational pressures and flow rates, making them suitable for conventional, directional, and horizontal drilling.

Saigao’s Manufacturing and Engineering Excellence

Backed by a robust technical foundation, Saigao Group integrates cutting-edge technology with over 300 high-precision processing units including CNC lathes, milling machines, grinding systems, and machining centers. The company’s dedicated research facilities ensure that every circulating sub is built to meet stringent international quality standards.

Each unit undergoes a thorough quality assurance process, from material selection and heat treatment to final pressure testing. This commitment to excellence ensures long service life, reliable sealing, and precise engagement under high-stress conditions. The resulting tools are trusted by clients worldwide, from Russia and Brazil to South Africa and Australia.

Enhancing Drilling Efficiency Through Innovation

The circulating sub is more than just a simple tool; it’s a strategic component that directly impacts operational safety, time efficiency, and cost-effectiveness. In today’s drilling landscape, where downtime can lead to massive financial loss, tools like Saigao’s circulating sub make a measurable difference.

By incorporating precision engineering and a deep understanding of field requirements, Saigao ensures its circulating sub are ready to perform under the most demanding conditions. As drilling technologies advance, the role of dependable, innovative tools becomes increasingly important. In this regard, the circulating sub stands out as a small but mighty element that empowers safer, faster, and more reliable drilling outcomes.