In the complex world of oil and gas drilling, maintaining a smooth and unobstructed borehole is essential for success. One tool that plays a pivotal role in achieving this is the casing reamer shoe. Designed to assist in navigating tight spots, collapsed formations, or obstructions during casing runs, the casing reamer shoe has become an indispensable solution in various difficult drilling environments. Saigao Group, with its deep technical expertise and manufacturing capability, provides robust and innovative casing reamer shoes to meet global industry demands.

Understanding the Function of a Casing Reamer Shoe

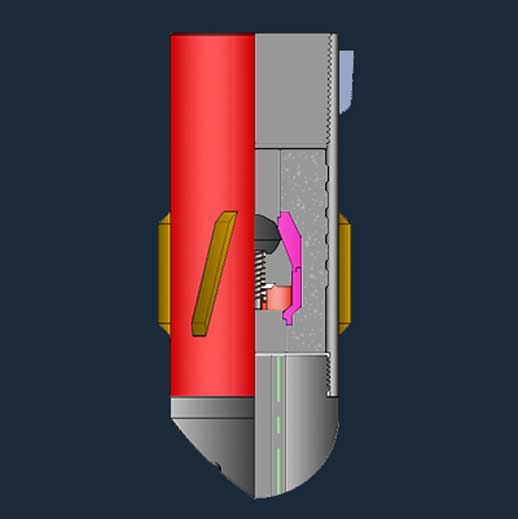

A casing reamer shoe is a downhole tool fitted to the bottom of a casing string. Unlike standard casing shoes that simply guide the casing into place, a reamer shoe is equipped with cutting or milling components that help enlarge or smooth the borehole as the casing is run. This is particularly useful in deviated wells, tight formations, swelling shales, or where hole conditions have deteriorated due to instability.

By reaming the wellbore while simultaneously advancing the casing, this tool reduces the risk of casing getting stuck and improves overall efficiency and safety. Saigao’s designs ensure that these tools can handle harsh environments, providing both reliability and performance.

Ideal Situations for Deploying a Casing Reamer Shoe

The casing reamer shoe proves most useful under specific downhole conditions. For instance, when encountering ledges, washouts, or doglegs, the tool’s cutting structure helps guide the casing through without delays. Additionally, in wells with swelling formations, where the borehole narrows over time, the reamer shoe helps reopen the hole enough for the casing to pass through smoothly.

Another key application arises when casing must be landed deeper than initially planned. The reamer shoe allows operators to push casing further downhole without requiring additional hole conditioning or re-drilling, saving both time and cost.

Comparing Standard Casing Shoe vs. Casing Reamer Shoe

To better understand when to use a casing reamer shoe, it's helpful to compare it with a standard casing shoe:

Feature |

Standard Casing Shoe |

Casing Reamer Shoe |

Primary Function |

Guide casing into borehole |

Ream/enlarge borehole + guide |

Cutting/Milling Ability |

None |

Yes |

Suitable for Obstructions |

No |

Yes |

Time Efficiency |

Moderate |

High |

Cost |

Lower |

Slightly higher (but saves more later) |

Typical Use Case |

Clean wells |

Unstable/difficult boreholes |

As seen in the table above, while standard casing shoes are adequate in clean, unobstructed holes, the casing reamer shoe is a clear advantage in problematic drilling scenarios.

The Saigao Approach to Reamer Shoe Engineering

At Saigao Group, a strong foundation in research, design, and manufacturing enables the production of high-performance casing reamer shoes. The company’s reamer shoes are engineered to handle the demands of both vertical and horizontal wells, incorporating aggressive cutting structures and wear-resistant materials. Advanced CNC machining equipment ensures product consistency, while rigorous quality testing guarantees field reliability.

Furthermore, the company’s diverse technical and testing centers reflect its ongoing commitment to innovation and product optimization. This capability allows Saigao to meet the unique requirements of drilling operations in different geological regions worldwide.

When Should You Choose a Casing Reamer Shoe?

In essence, if your drilling plan includes passing through unpredictable or challenging zones—such as soft shale, collapsed formations, or doglegs—the casing reamer shoe becomes not just a helpful option but a necessity. It minimizes non-productive time, enhances wellbore integrity, and significantly improves casing success rates. For contractors and operators seeking to increase reliability while reducing costs and risks, using a casing reamer shoe from a trusted manufacturer like Saigao is a wise strategic choice.