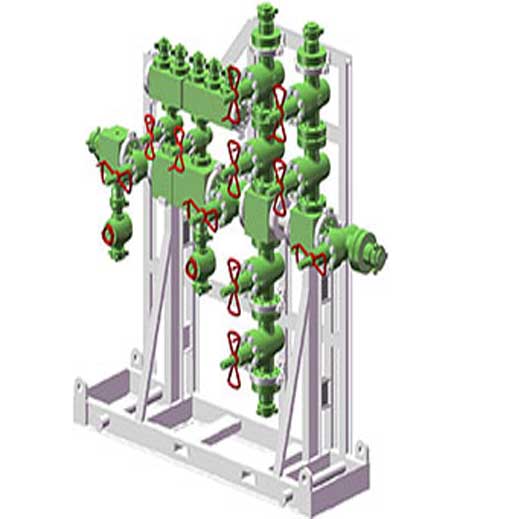

In the complex and high-pressure environment of drilling operations, every component plays a critical role in ensuring safety, precision, and efficiency. One such essential component is the standpipe manifold, a key system responsible for regulating and directing high-pressure drilling fluid from the mud pump to the drilling rig. Saigao, a leading manufacturer in the oil and gas equipment sector, offers precision-engineered standpipe manifold that reflect its deep-rooted expertise in design, development, and manufacturing.

The standpipe manifold acts as a central artery in the drilling fluid circulation system. It serves as the vital connection between the mud pumps and the drill string, ensuring continuous and controlled flow of drilling fluids under high pressure. By providing a stable conduit, it minimizes pressure fluctuations and enhances operational consistency. This is especially important in deep drilling environments where any inconsistency in fluid pressure could compromise safety and efficiency.

Saigao's standpipe manifold systems are built with advanced technology and undergo strict quality testing using the company’s sophisticated machining centers and equipment. These systems are designed to withstand extreme pressure environments, aligning perfectly with Saigao’s commitment to durability and precision.

Modern drilling operations rely on high-capacity, automated systems where each component must seamlessly integrate with the whole. Saigao's standpipe manifold are designed for compatibility with a wide range of marine and land-based drilling platforms. Their precise engineering ensures that they align accurately with mud pumps, valves, and control systems. The modular design further simplifies maintenance and replacement, reducing operational downtime.

As Saigao continues to develop advanced oilfield machinery, its standpipe manifold are continuously refined to meet the evolving demands of complex drilling conditions. The use of CNC equipment and state-of-the-art manufacturing processes ensures these manifolds meet global quality and performance standards.

Safety is a primary concern in high-pressure drilling environments. The standpipe manifold must operate without leaks or failures to prevent blowouts or drilling fluid loss. Saigao’s strict quality control processes, combined with their advanced testing facilities, ensure each standpipe manifold meets or exceeds safety standards. Their use of high-performance materials and precise assembly techniques guarantees consistent performance under extreme conditions.

Moreover, Saigao’s technical expertise, supported by its provincial-level technical center and dedicated mud pump detection facility, ensures that every manifold is optimized for maximum reliability and lifespan. These systems play a critical role in mitigating risks and enhancing crew safety on drilling platforms.

Saigao’s standpipe manifold have been widely adopted across drilling sites in Russia, Brazil, Australia, South Africa, and more. Their proven performance in varied geological conditions underscores their versatility and global appeal. As part of Saigao's broader product line — which includes mud pumps, down-hole tools, and wellhead equipment — the standpipe manifold benefits from the company’s decades of engineering innovation and field experience.

In conclusion, the standpipe manifold is not just a conduit—it’s a critical link in the drilling chain that impacts safety, efficiency, and operational success. Saigao’s dedication to high-quality manufacturing, rigorous testing, and global standards makes its standpipe manifold systems a preferred choice in the international oil and gas industry. As drilling technology continues to evolve, Saigao remains committed to delivering components that meet the challenges of tomorrow's energy needs.