Water softening is a critical process across a wide range of industries, particularly in sectors such as petroleum, geothermal drilling, construction, and water supply systems. One key technology that plays a foundational role in efficient water filtration during softening treatment is the wire wrapped screen. Known for its mechanical strength and precise filtration capabilities, this tool is essential in separating unwanted particles and improving water quality. Saigao Group, leveraging decades of industrial expertise, produces high-performance wire wrapped screens that are increasingly used in softening systems for both industrial and environmental applications.

The Role of Wire Wrapped Screen in Water Softening

Water softening involves removing minerals such as calcium and magnesium, which cause hardness. In many softening processes, water is passed through beds of resins or media where ion exchange or precipitation occurs. Before entering these beds, however, it is crucial to filter out sediment, suspended solids, and particulates that could clog the softening system or reduce its efficiency. This is where a wire wrapped screen proves vital.

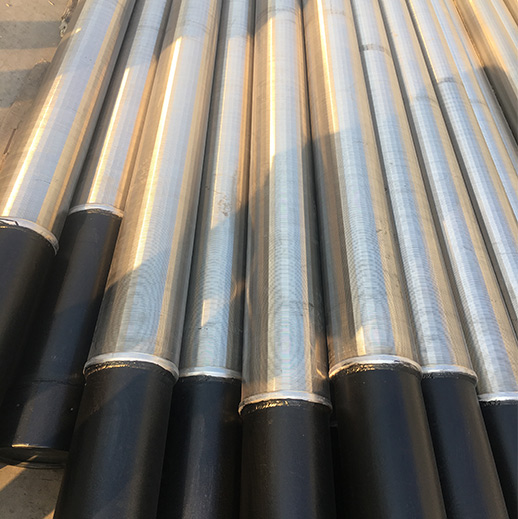

A wire wrapped screen acts as the first line of defense by allowing only water and fine dissolved ions to pass through, while larger solids are trapped on the screen surface. Its V-shaped wire design and continuous slot construction prevent clogging and enable longer filtration cycles, making the overall water softening process more consistent and cost-effective.

Comparison of Wire Wrapped Screen and Traditional Filters

Feature | Wire Wrapped Screen | Traditional Mesh Filters |

Filtration Efficiency | High, due to V-wire slot design | Moderate, prone to clogging |

Clogging Resistance | Excellent, with self-cleaning capabilities | Poor, frequent maintenance required |

Material Durability | Stainless steel or alloy, corrosion-resistant | Often plastic or basic metal |

Lifespan | Long, with minimal maintenance | Shorter, needs frequent replacement |

Flow Rate | High, uninterrupted fluid movement | Reduced over time as clogging occurs |

As this comparison shows, a wire wrapped screen offers superior durability, flow consistency, and filtration accuracy, making it an ideal fit for water softening applications in both industrial and municipal contexts.

Structural Advantages and Durability

Saigao's wire wrapped screens are manufactured with high-precision NC equipment and undergo rigorous quality testing. This ensures excellent dimensional stability and corrosion resistance. The V-shaped wires are welded onto support rods, creating slots that are narrower at the surface than at the base. This not only improves structural integrity but also reduces the likelihood of blockage caused by particulate buildup.

Due to their stainless steel or anti-corrosive alloy construction, these screens can operate in highly alkaline or chemically treated water environments. This resistance to corrosion and wear is essential in water softening, where chemical reactions and high flow rates can degrade traditional filtration elements quickly.

Application Flexibility in Softening Systems

Wire wrapped screens from Saigao are available in various sizes and slot configurations, which means they can be customized for different stages of the softening process. Whether used as an outer shell in resin trap systems or as stand-alone pre-filters, they perform equally well. These screens can also be used in both vertical and horizontal configurations, which allows engineers to integrate them into existing or newly designed water treatment infrastructure seamlessly.

Additionally, their high mechanical strength ensures they can withstand pressure surges and fluctuations without deformation. This makes them especially valuable in applications such as geothermal or shale gas projects, where water quality varies and pressure changes are frequent.

Improving Efficiency and Sustainability

In water softening systems, operational efficiency translates directly into cost savings and environmental benefits. By reducing the frequency of backwashing and extending the life of downstream ion exchange media, the use of wire wrapped screens can lower energy consumption and chemical use. Saigao's commitment to high-quality engineering ensures that each screen contributes not only to smoother system operation but also to more sustainable water management practices.

Moreover, with global water scarcity concerns mounting, the need for reliable and efficient filtration technologies becomes even more critical. Wire wrapped screens offer a scalable, low-maintenance, and high-performance solution that aligns well with modern water treatment demands.

In conclusion, the wire wrapped screen serves as a critical component in the water softening process, particularly in industrial-scale and high-efficiency applications. With its precise design, robust construction, and anti-clogging capabilities, it supports sustainable and uninterrupted water treatment operations. Saigao Group’s industry expertise and advanced manufacturing capabilities ensure that their wire wrapped screens meet the evolving needs of global markets while delivering reliable performance in the most demanding environments.