In the quest for maximizing hydrocarbon recovery and maintaining safe production levels, the oil well choke valve emerges as a critical component. By precisely regulating flow and pressure at the wellhead, choke valves enable operators to adapt to changing reservoir conditions, protect downstream equipment, and optimize overall extraction efficiency. Drawing on Saigao Group’s extensive experience in designing and manufacturing high-performance drilling equipment, today’s choke valves marry advanced materials with precision engineering to meet the rigorous demands of modern petroleum operations.

Mastering Pressure Control for Enhanced Recovery

Effective pressure management is the cornerstone of efficient production. The oil well choke valve functions as a variable orifice that throttles wellhead fluids to maintain a desired differential pressure between the reservoir and surface equipment. By fine-tuning this back-pressure, operators can prevent abrupt pressure drops that might lead to gas breakout or sand production, both of which can impair well performance. Saigao’s choke valves, crafted from high-grade alloys and CNC-machined to exact tolerances, deliver smooth, repeatable adjustments, ensuring consistent drawdown and maximizing ultimate recovery from the reservoir.

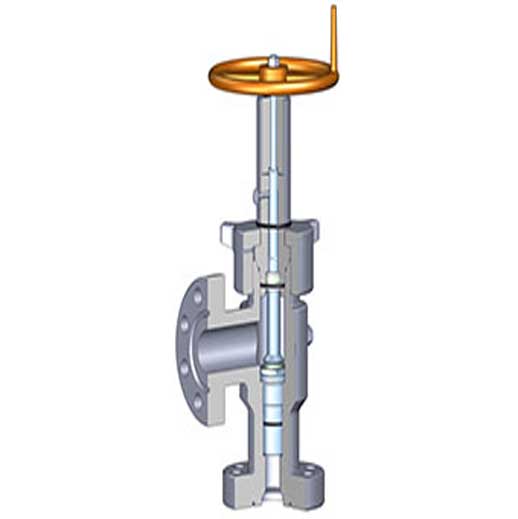

Tailoring Valve Selection to Well Conditions

Each well presents its own challenges: from high GOR (gas-oil ratio) wells prone to slugging, to heavy oil wells demanding elevated injection pressures. Selecting the right oil well choke valve involves considering factors such as expected flow rates, fluid composition, operating temperature, and erosion potential. Saigao offers both fixed-and adjustable-choke designs, allowing operators to choose a solution that balances cost, flexibility, and maintenance needs. Fixed chokes excel in long-term, stable production scenarios, while adjustable models provide the versatility to respond rapidly to fluctuating conditions without pulling the toolstring.

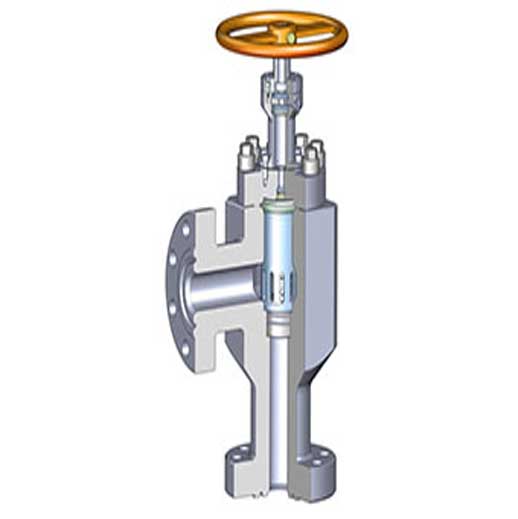

Durability Under Duress

The erosive nature of sand-laden fluids and corrosive gases demands that oil well choke valves possess exceptional wear resistance and chemical stability. Saigao employs specially selected stainless steels and nickel-based alloys in its valve bodies and trims, alongside hardened tungsten carbide or stellite seats. These material choices, coupled with precision grinding and surface treatments, minimize erosion and ensure reliable performance even under high differential pressures. The result is a choke valve that maintains flow characteristics and sealing integrity over extended production intervals.

Integrating Automation for Real-Time Optimization

Advancements in downhole monitoring and surface controls have driven the integration of choke valves into automated production optimization systems. When equipped with electric or hydraulic actuators, the oil well choke valve becomes a dynamic control element in a closed-loop environment. Saigao’s automated choke solutions can receive real-time data on pressure, temperature, and flow from SCADA platforms, enabling rapid adjustments that stabilize production and protect against sudden reservoir or equipment anomalies. By embedding intelligence into choke operation, operators can reduce manual interventions and improve overall field economics.

Driving Sustainable Production Practices

Beyond immediate efficiency gains, the oil well choke valve contributes to longer-term asset integrity and environmentally conscious production. By preventing sand influx and controlling gas flaring through stabilized flow, choke valves help reduce equipment wear, minimize unplanned shutdowns, and limit methane emissions. Saigao’s commitment to “Customer First; Quality First” extends to manufacturing processes that comply with international standards, ensuring that each choke valve not only enhances extraction rates but also supports responsible stewardship of subsurface resources.

Through precise pressure control, material resilience, and automation readiness, the oil well choke valve stands as a keystone in modern petroleum production. Saigao Group’s decades of engineering expertise and global manufacturing capacity ensure that operators worldwide can rely on their choke solutions to drive safer, more efficient, and more sustainable hydrocarbon recovery.